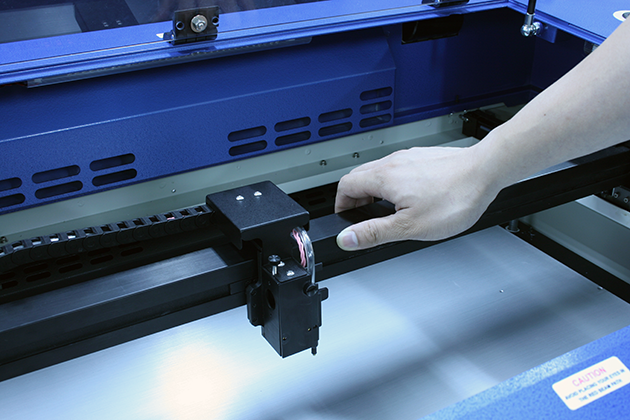

Drag-N-Play

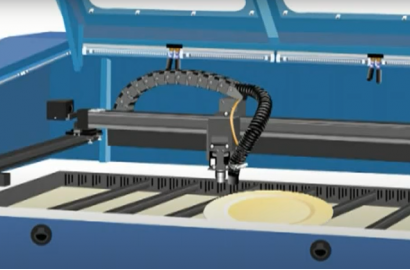

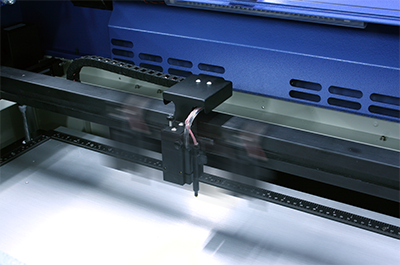

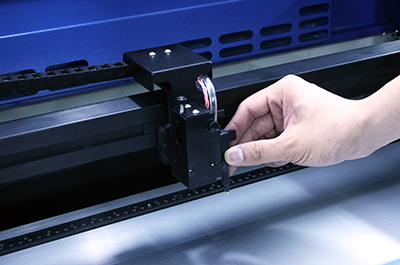

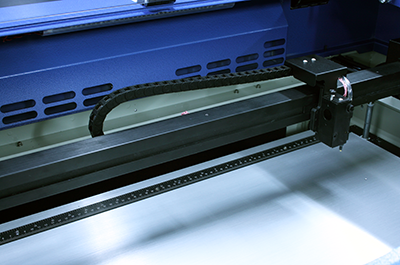

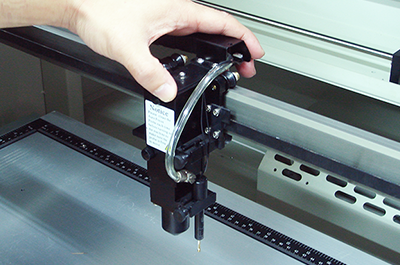

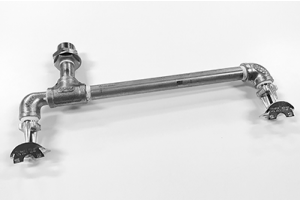

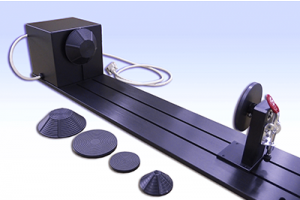

An exceptionally innovative and user-friendly feature based on servomotor technology simplifies operations and shortens setup time. Simply hand drag the lens carriage to the desired position to be engraved and press the start button to commence job.

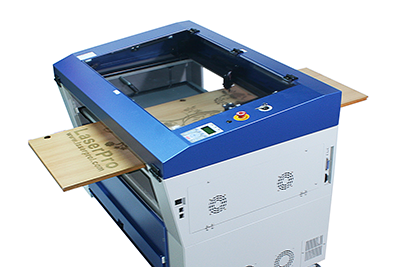

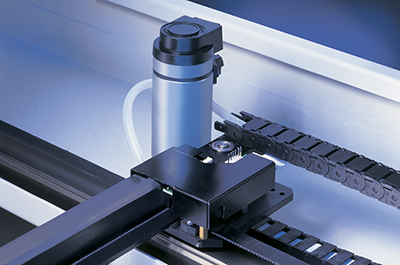

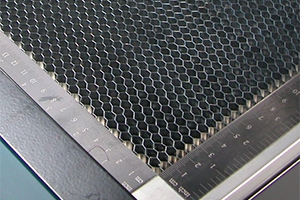

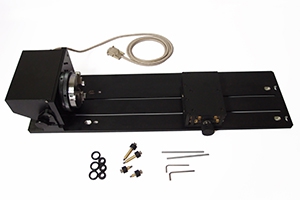

Closed-loop DC Servo Technology

Closed-loop DC Servo Technology

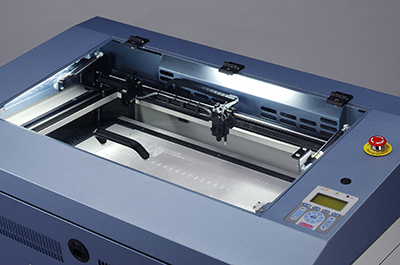

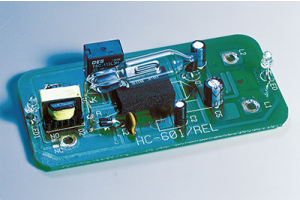

– For USB storage (Max. 32GB capacity, FAT file system)

– For USB storage (Max. 32GB capacity, FAT file system)  – For connecting with the computer

– For connecting with the computer