Metal Engraving with LaserInk | Laser Engraving, Vinyl Cutter, UV Printer - GCC

Widely applied in the market, CO2 Laser, which enjoys the advantage of its versatility because of the great number of applicable materials and lower prices compared to other laser resources, is mainly used in many processing centers. CO2 Laser, which is ideal for the processing of most materials, does not work perfectly on metals due to its wavelength. Has the thought of acquiring other laser resources given you a headache when there is only a small amount of metallic materials needing to be processed?

The GCC LaserPro application Lab of the month introduces LaserInk—your best solution. All you need is evenly spread or spray LaserInk, a coating specially designed for metals, on metallic materials prior to your processing procedure with CO2 Laser when the coating turns dry. Tempted by such simple steps? See the following demonstration by GCC LaserPro now!

Materials needed:

- Various metallic materials

- LaserInk

Processing procedure:

Step 1. Spread or spray mixed LaserInk on the material to be engraved.

Step 2. Place the material on the working table when the coating turns dry.

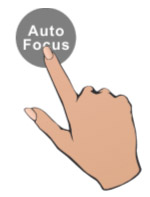

Step 3. Target the focusing bar on the material and press "Autofocus" to automatically set the focal distance.

Step 4. Press the “Start” key to start processing the material.

Step 4. Press the “Start” key to start processing the material.

Step 5. Rinse off excessive LaserInk on the engraved material with water.

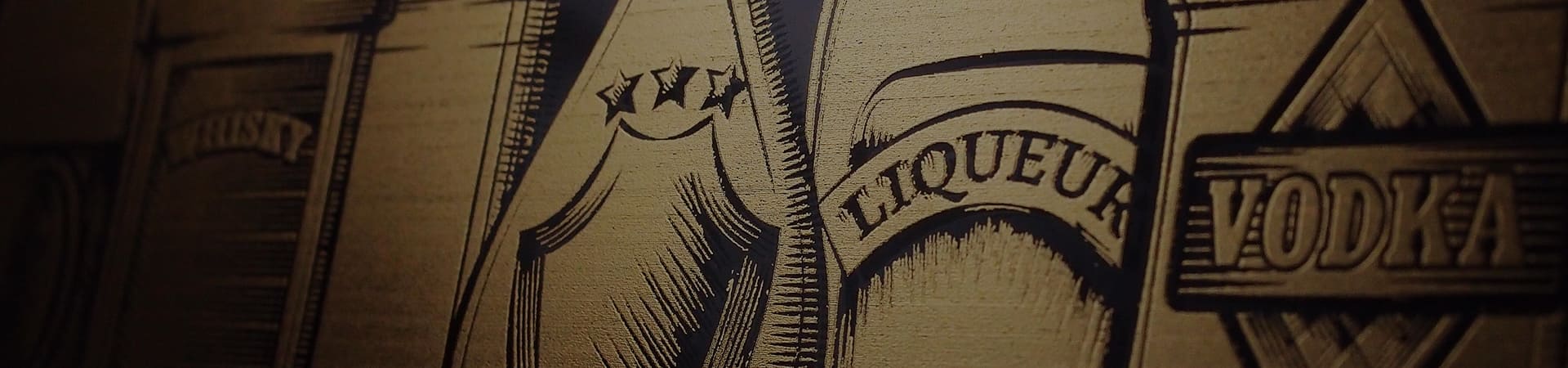

Step 6. Complete sample.

Suggested parameters:

| C180II 30W | ||||

| Speed | Power | DPI | PPI | Other |

| 30 % | 80 % | 500 | 400 | Error Diffusion |

*The parameters are for suggestions only and should be moderately adjusted accordingly.

Tips:

- Ensure the material is evenly placed to prevent the laser beam from going out of focus which might lead to waste of materials.

- Please spread/ spray the coating evenly on the material to avoid defective engraving samples.