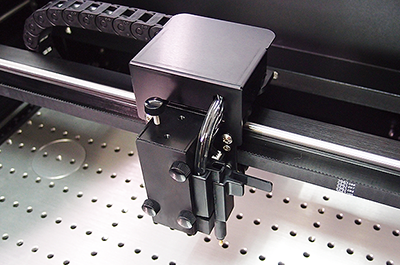

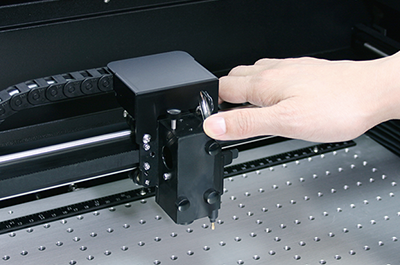

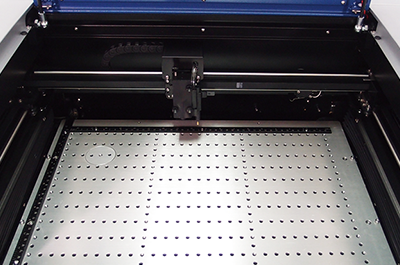

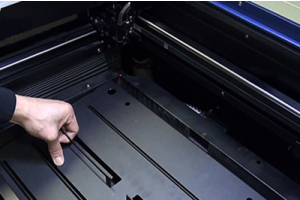

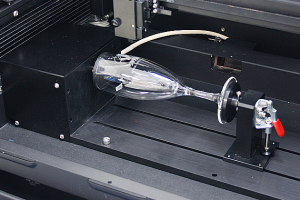

Closed-loop DC Servo Motor and Reliable Motion System

The C180II utilizes high performance Closed-loop DC servo motors for precise and fast carriage movement combined with a reliable motion system to produce exceptionally accurate outputs.

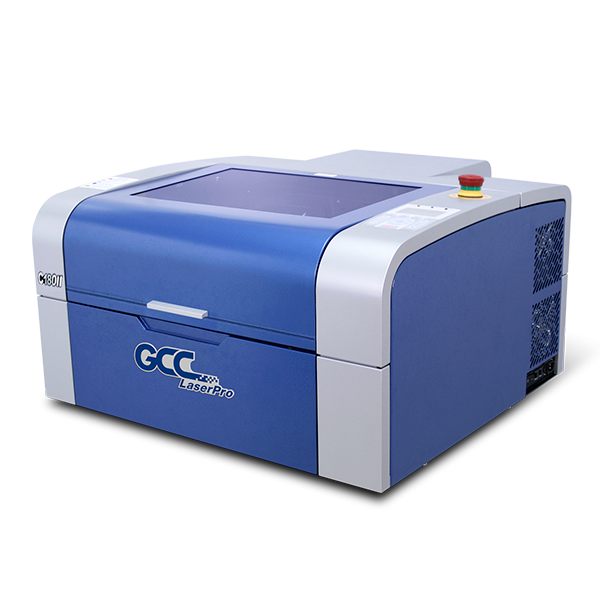

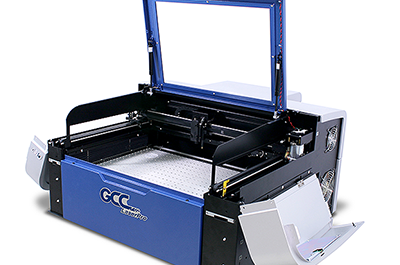

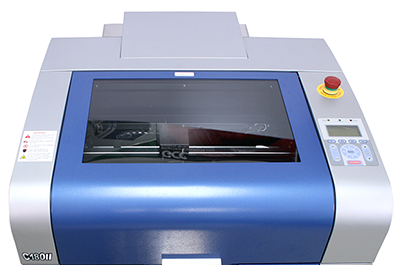

| C180II | |

|---|---|

| Work Area | 18 in. x12 in. (458 mm x 305 mm) |

| Max. Part Size (L x W x H) | 19.8 x 12.2 x 6 in. (503 x 310 x 152.4mm) |

| Table Size | 20.4 in. x14.7 in. (520 mm x 375 mm) |

| Dimensions | 30.7 x 29.1 x 16.1 in. (780 x 740 x 410 mm) |

| Laser Source | 12 to 40 Watt Sealed CO2 Laser |

| Cooling | Air-cooled, Operating environment temperature 15°-30°C (60°-86°F) |

| Drive | Closed-loop DC Servo Control |

| Maximum Motor Speed | 40 IPS |

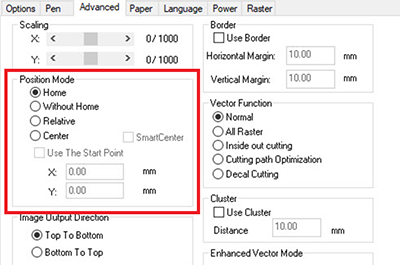

| Speed Control | Adjustable from 0.1~100% (Up to 16 color-linked speed settings per job) |

| Power Control | Adjustable from 0~100% (Up to 16 color-linked power settings per job) |

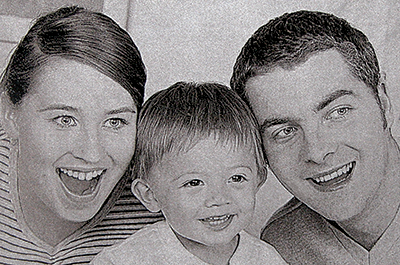

| Engraving Capability | 256-level gray scale image processing capability |

| Distance Accuracy | 0.254 mm or 0.1% of move. whichever is greater |

| Z-Axis Movement | Automatic |

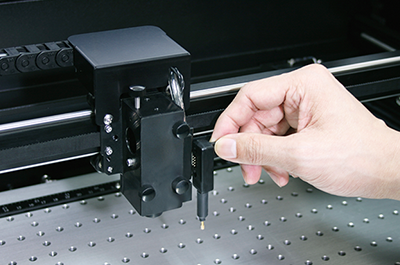

| Focus Lens | Standard 2.0", optional 1.5" available |

| Resolution (DPI) | Available 125, 250, 300, 380, 500, 600, 760, 1000 |

| Interface | 10 Base-T Ethernet USB Type-A 2.0  – For USB storage (Max. 32GB capacity, FAT file system) – For USB storage (Max. 32GB capacity, FAT file system) USB Type-B 2.0  – For connecting with the computer – For connecting with the computer |

| Compatible Operating Systems | MS Windows |

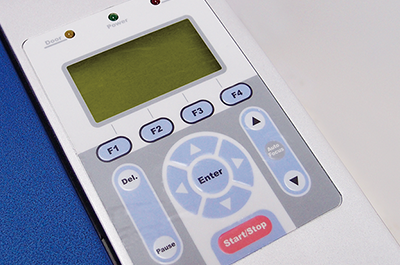

| Display Panel | 4-line LCD panel showing current file name, total working time, laser power, engraving speed, file(s) loaded into memory buffer, setup and diagnostic menus. |

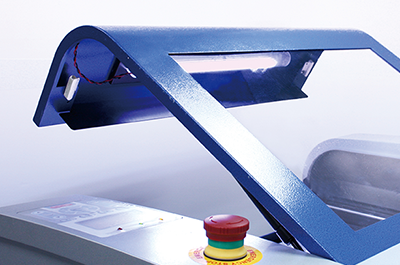

| Safety | Class I Laser Product Compliant with EN60825 Class II Laser Product Compliant with CDRH 2006/42/EC Machinery Directive Compliance |

| Facility Requirements | |

| Operation Voltage | 100-240VAC, 50-60Hz Auto Switching, Max. 15A |

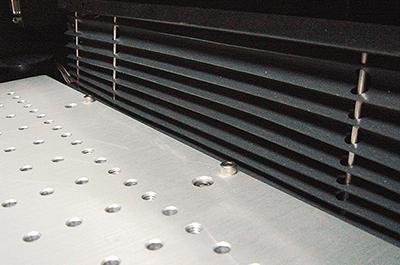

| Fume Extraction System | External exhaust system with minimum flow rate 215m3/h (CFM 125 ft3/h) is required, 10kPA negative pressure (Purex GCC 400 @ 2"& 4" exhaust port) |

| *Speed is not equal throughput. See dealer or visit http://www.gccworld.com for more details. | |