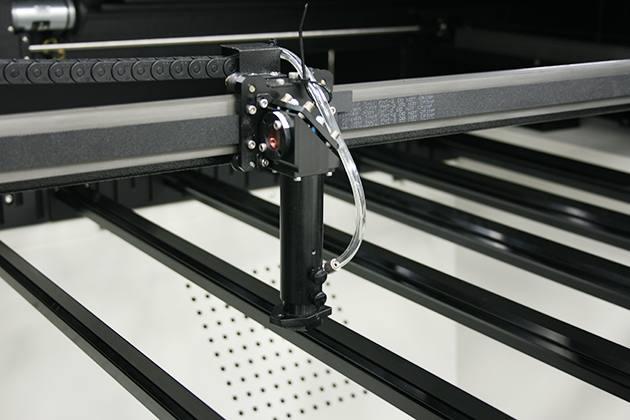

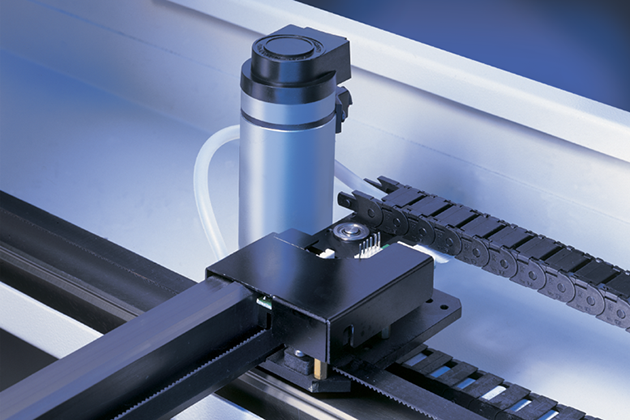

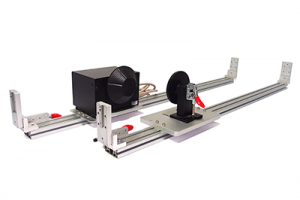

Drag-N-Play

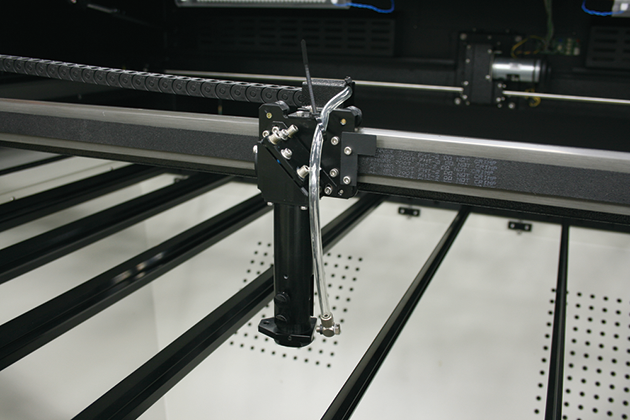

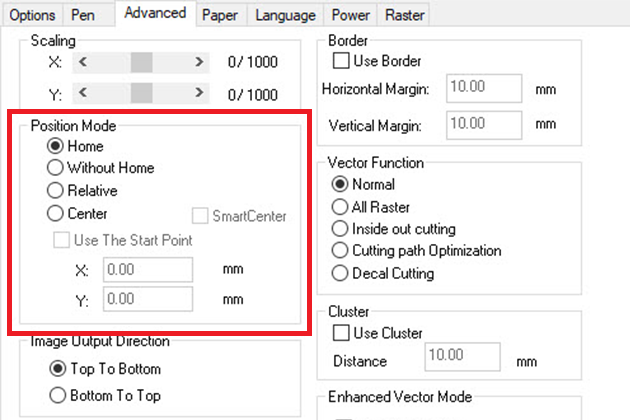

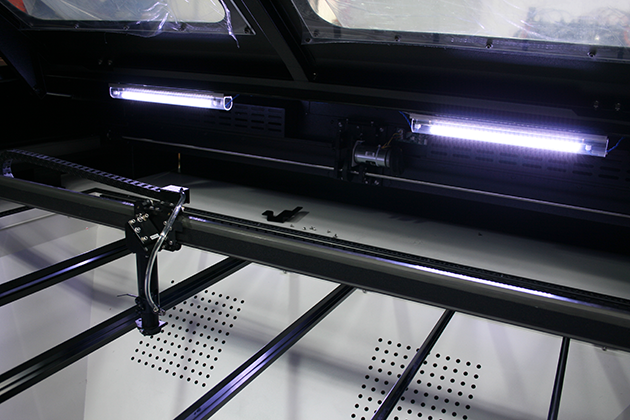

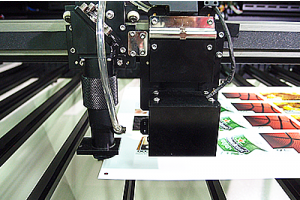

The “Drag-N-Play” feature greatly reduces complex set up procedures and allows users to directly drag the lens carriage to the starting point of a job.

| X500III | |||||

|---|---|---|---|---|---|

| Laser Source | 80W | 100W | 130W | 150W | |

| Sealed CO2 Laser | |||||

| Laser Cooling | Water Cooled | ||||

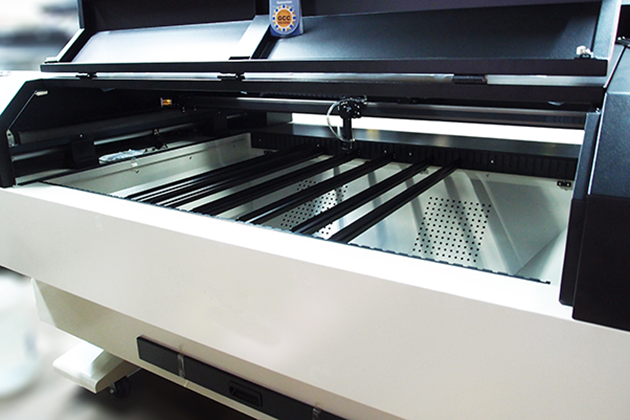

| Working Area | w/o Honeycomb Table | 51 x 36 in. (1300 x 916 mm) | |||

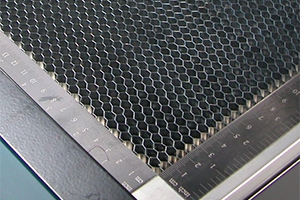

| with Honeycomb Table | 50.3 x 35.2 in. (1280 x 896 mm) | ||||

Max. Part Size (L x W x H) | w/o Cutting Table | 52.9 x 36.0 x 2.1 in. (1346 x 916 x 55 mm) | |||

| Doors Open | 52.9 x ∞ x 1.1 in. (1346 x ∞ x 30 mm) | ||||

| with Honeycomb Cutting Table | 48.8 x 32.2 x 1.1 in. (1240 x 818 x 30 mm) | ||||

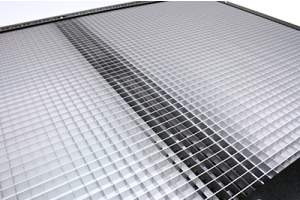

| with Grid Cutting Table | 52.1 x 35 x 1.1 in. (1325 x 889 x 30 mm) | ||||

| Dimensions | 74.8 x 55.1 x 47.2 in. (1900 x 1400 x 1200 mm) | ||||

| Driving Motor | Closed-loop DC servo control | ||||

| Maximum Motor Speed | 40 IPS | ||||

| Speed Control | Adjustable from 0.1~100% (Up to 16 color-linked speed settings per job) | ||||

| Power Control | Adjustable from 0~100% (Up to 16 color-linked power settings per job) | ||||

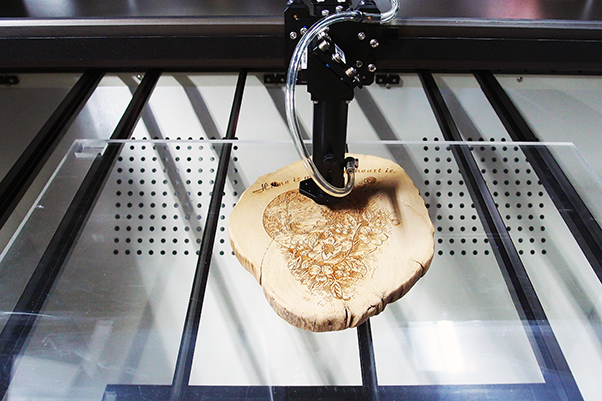

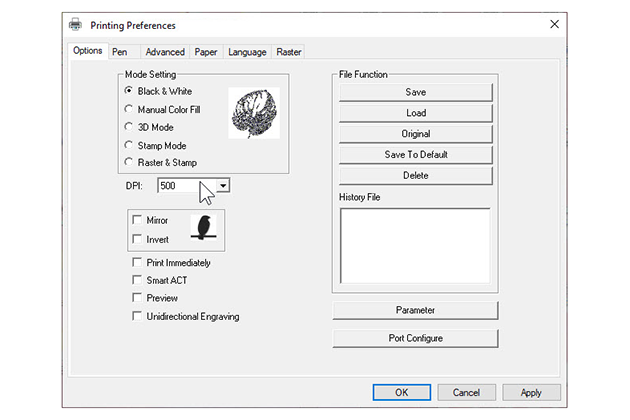

| Engraving Capability | 256-level gray scale image processing capability | ||||

| Distance Accuracy | 0.254 mm or 0.1% of move, whichever is greater | ||||

| Z-Axis Movement | Manual | ||||

| Resolution (DPI) | Available 125, 250, 300, 500, 600, 1000 | ||||

| Interface | 10 Base-T Ethernet USB Type-A 2.0  – For USB storage (Max. 32GB capacity, FAT file system) – For USB storage (Max. 32GB capacity, FAT file system) USB Type-B 2.0  – For connecting with the computer – For connecting with the computer | ||||

| Focus Lens | Standard 2",Optional 3" | Standard 3",Optional 2" | |||

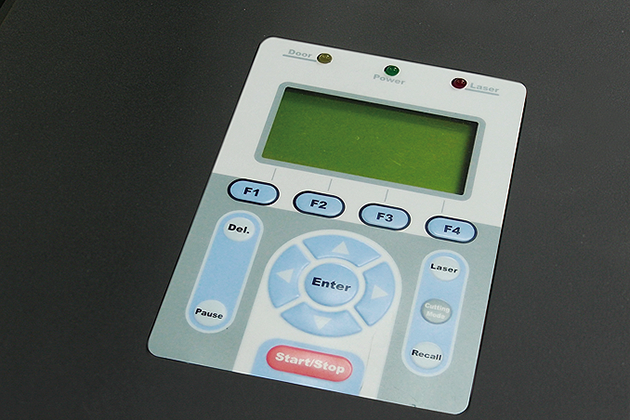

| Display Panel | 4-line LCD panel showing current file name, total working time, laser power, engraving speed, file(s) loaded into memory buffer, setup and diagnostic menus. | ||||

| Safety | Class I Laser Product Compliant with EN60825 Class II Laser Product Compliant with CDRH 2006/42/EC Machinery Directive Compliance Class 4 Laser Product Compliant with CDRH with the optional pass-through door module | ||||

| Cutting Table | Knife-shaped cutting bars with down vacuum and scrap collecting funnel | ||||

| Facility Requirements | |||||

| Operation Voltage | 200-240VAC, 50/60Hz auto switching, Max.10A | ||||

| Fume Extraction System | External exhaust system with minimum flow rate 2160m3/h (CFM 1273 ft3/h) is required,2.5kPA negative pressure (Pure-Air PA-2400FS @ 8" exhaust port) | ||||

| *Speed is not equal to throughput. See dealer or visit www.GCCworld.com for more details. | |||||