Easy-to-use Control Panel

A control panel with coherent hot-key design and graphic icon displays that allows you to directly change the laser parameter setting, set jobs to repeat unlimited times, queue job, delete jobs, and more.

| X252RX | ||

|---|---|---|

| Laser Source | 80W / 100W | |

| Sealed CO2 Laser | ||

| Laser Cooling | Water Cooled | |

| Working Area | 25 in. x18 in. (635 x 458 mm) | |

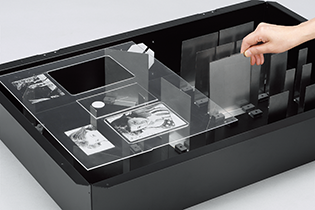

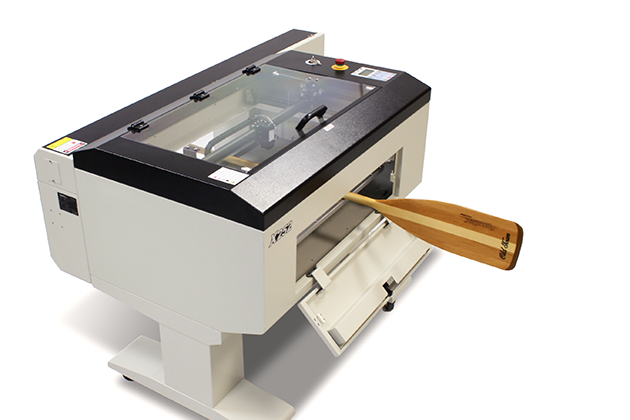

Max. Part Size (L x W x H) | All doors closed | 27 x 19 x 6.5 in. (685 x 482 x 165 mm) |

| All doors open | 27 x ∞ x 6.5 in. (685 x ∞ x 165 mm) | |

| Table Size | 31.1 x 20.9 in. (790 x 530 mm) | |

| Dimensions | 64.9 x 36.6 x 40.9 in. (1650 x 930 x 1040mm) | |

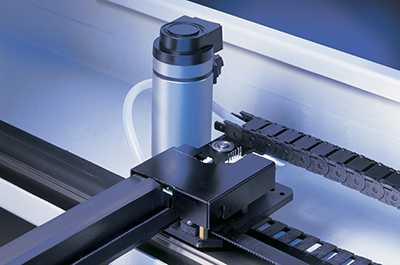

| Driving Motor | Closed-loop DC servo control | |

| Maximum Motor Speed | 40 IPS | |

| Speed Control | Adjustable from 0.1~100% (Up to 16 color-linked speed settings per job) | |

| Power Control | Adjustable from 0~100% (Up to 16 color-linked power settings per job) | |

| Engraving Capability | 256-level gray scale image processing capability | |

| Distance Accuracy | 0.254 mm or 0.1% of move, whichever is greater | |

| Resolution (DPI) | Available 125, 250, 500, 1000 | |

| Z-Axis Movement | Automatic | |

| Focus Lens | Standard 2.0", Optional 1.5", 3" | |

| Interface | 10 Base-T Ethernet USB Type-A 2.0  – For USB storage (Max. 32GB capacity, FAT file system) – For USB storage (Max. 32GB capacity, FAT file system) USB Type-B 2.0  – For connecting with the computer – For connecting with the computer | |

| Compatible Operating Systems | MS Windows | |

| Safety | Class I Laser Product Compliant with EN60825 Class II Laser Product Compliant with CDRH 2006/42/EC Machinery Directive Compliance Class 4 Laser Product Compliant with CDRH with the optional pass-through door module | |

| Facility Requirements | ||

| Operation Voltage | 200-240VAC, 50/60Hz Auto Switching, MAX. 8A. | |

| Water Chiller | External water chiller required | |

| Fume Extraction System | External exhaust system with minimum flow rate 640m³/h (CFM 377 ft³/h) is required, 2.3kPA negative pressure (Pure-Air PA-1000FS @ 4" exhaust port) | |

| *Speed is not equal to throughput. See dealer or visit www.GCCworld.com for more details. | ||