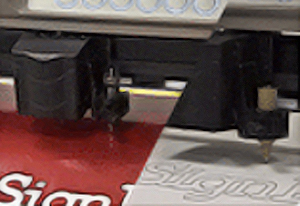

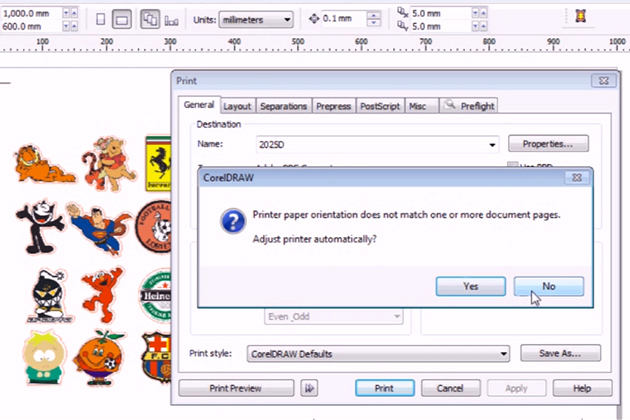

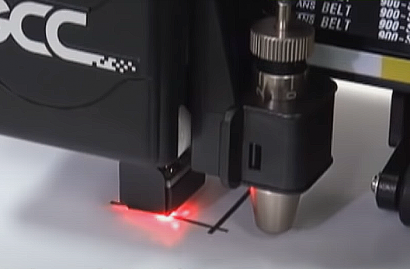

Enhanced AAS II Contour Cutting System (Only for Puma IV LX Model)

The Puma IV series features a standard Automatic-Aligning System(AAS II) to guarantee precise contour cutting by detecting the registration marks on digitally produced images. Functions include:

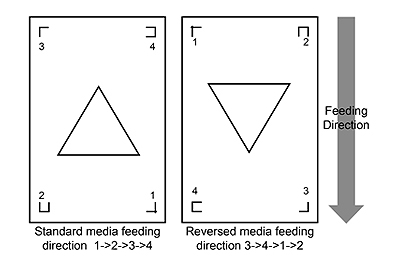

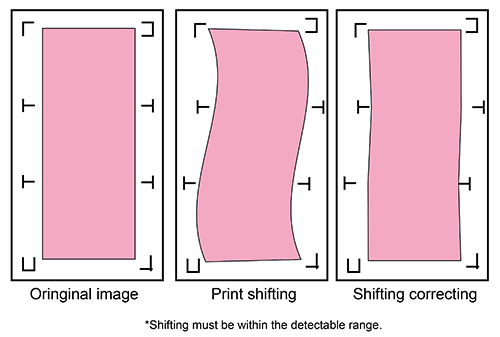

1st-mark auto-detection 1st-mark auto-detection |  4-point positioning 4-point positioning |

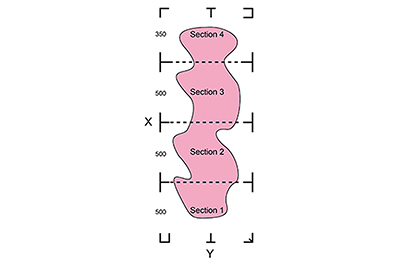

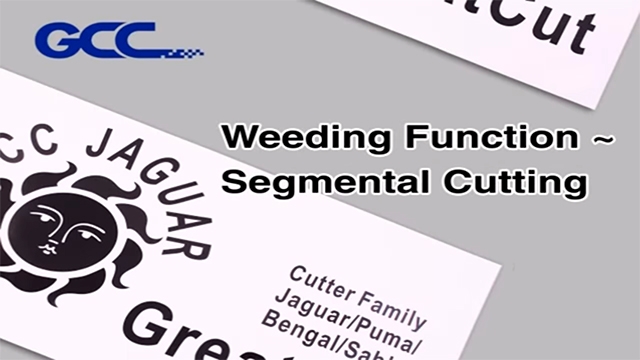

Segmental positioning Segmental positioning |  Multiple copies Multiple copies |