Creating Personalized Stickers Using GCC Cutting Plotters | Laser Engraving, Vinyl Cutter, UV Printer - GCC

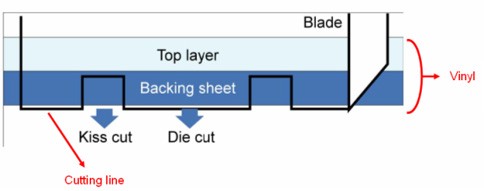

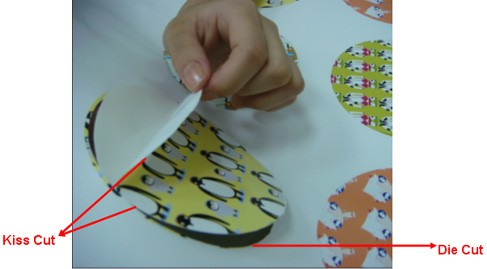

The Die Cut function allows users to cut through the backing of the material and you can easily set up the length and force of die cut and kiss cut cutting line at the same job. This feature applies to different applications such as stickers and prototype of boxes, perfect for business owners who would like to provide customized and unique products.

* Die Cut cuts through the backing of the material

Kiss Cut (half cut) only cuts through the vinyl but not the backing sheet

You can now start creating your own personalized sticker by simply following the steps below:

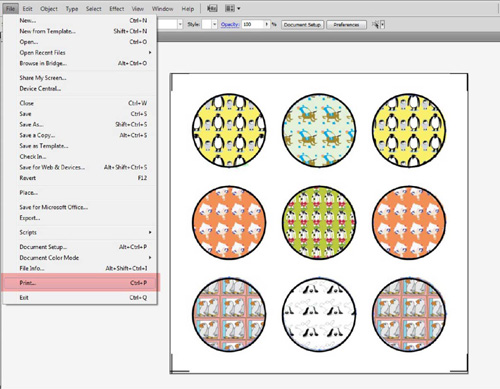

Step 1:

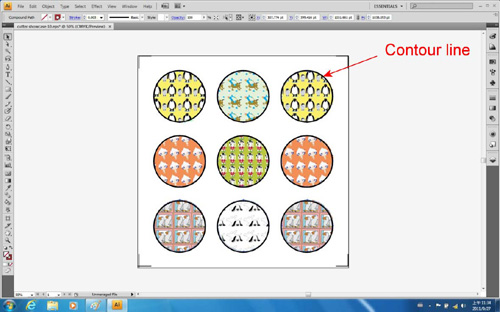

Create an image with a contour line and registration marks on Adobe Illustrator and then print it out.

Step 2: Place the printed file on the cutter and position the carriage at the origin of the registration mark.

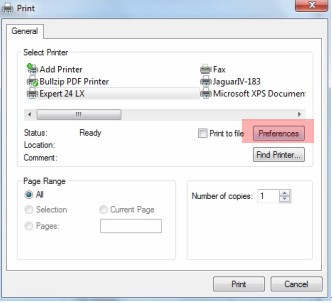

Step 3: Process to the Die Cut function setting by clicking “print” under “file”.

Step 4: Select the cutter model and go to “Preferences”.

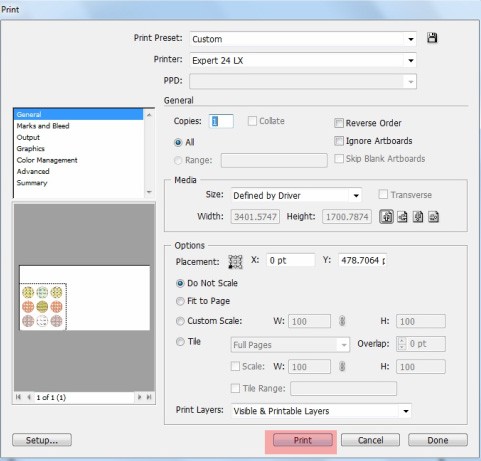

Step 5: Go to “Option”, tick “Die Cut”, and enter the amount you wish for the “Length” and “Force” of both Die Cut and Kiss Cut, then click “OK ”.

Range of length setting:

Die Cut: 0-2000mm

Kiss Cut: 0-100mm

Step 6: Click “Print” when you go back to the General page after the Die Cut setting is completed and the cutting plotter will start working.

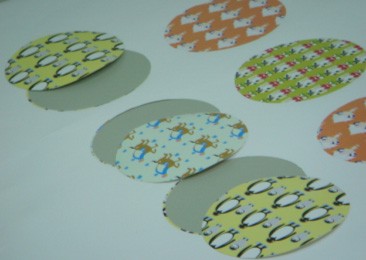

Samples:

Reference Parameters

| Die Cut | Kiss Cut | |

| Length | 28 mm | 2 mm |

| Force | 150 g | 40 g |

| Speed | 18 cm/s | |

| Offset | 0.275 | |

| Quality | Small letter | |

- Parameters are for reference only. Please adjust the parameters according to the application and material you are working on.

- The extension of the blade has to be set to cut through both the top layer and the backing in the very beginning. You then adjust the tool force for the best cutting performance.

- Once the Die Cut function is activated, it will perform on all the line segments on the object.