Fiber Laser on Plastic Materials | Laser Engraving, Vinyl Cutter, UV Printer - GCC

Materials:

| ||||||||||

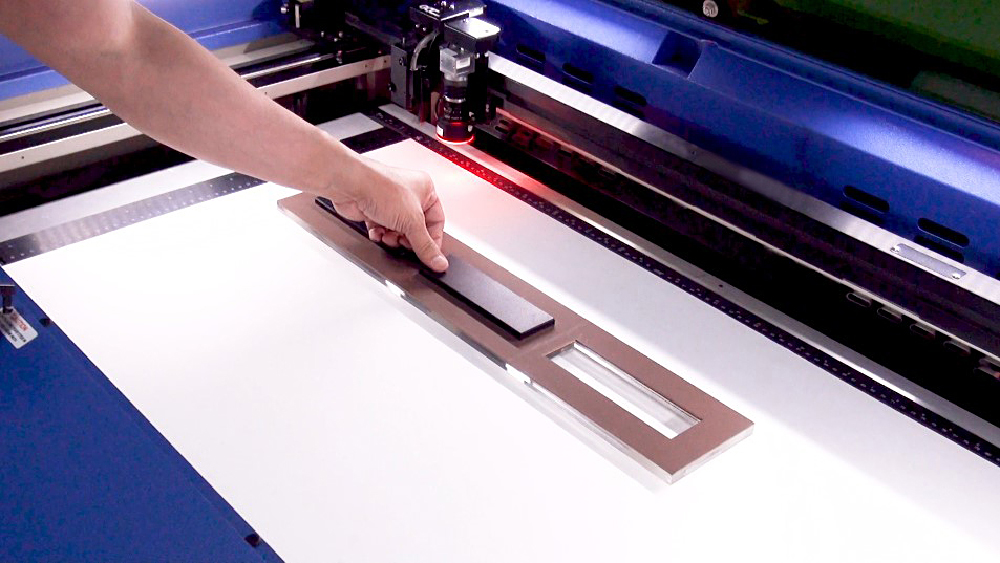

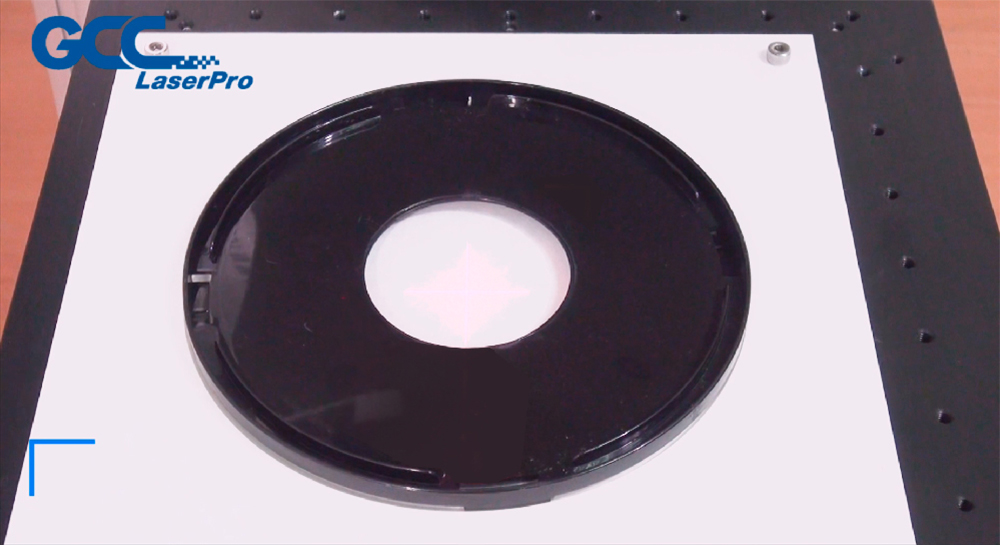

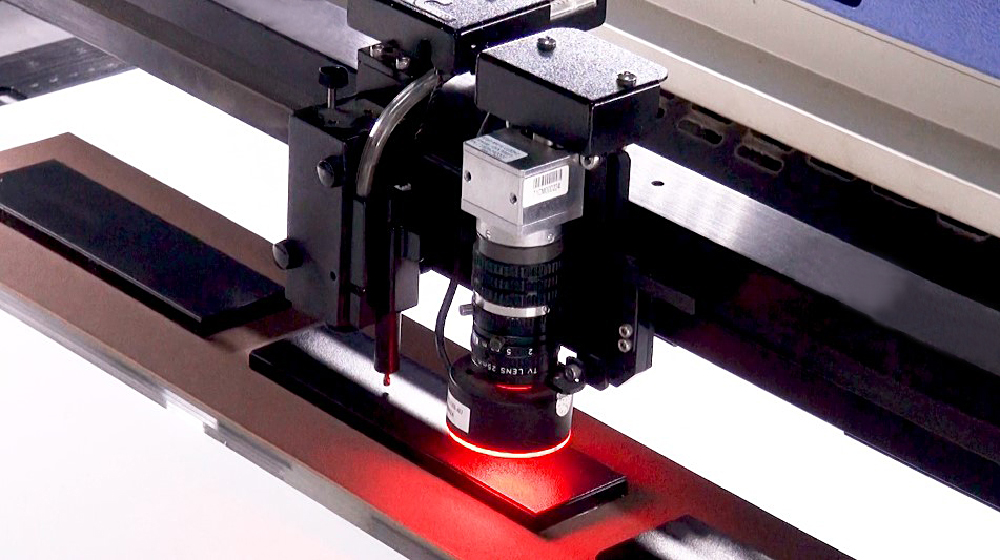

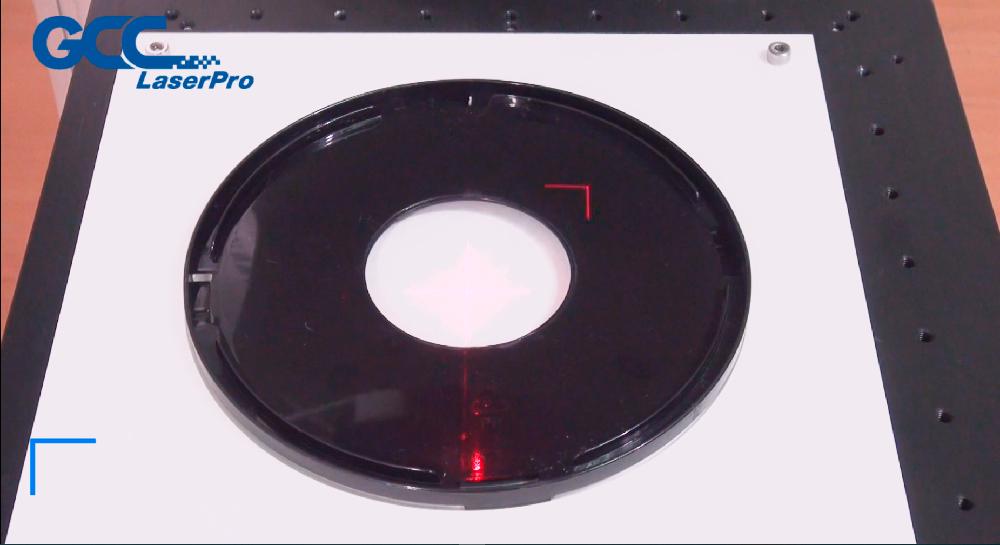

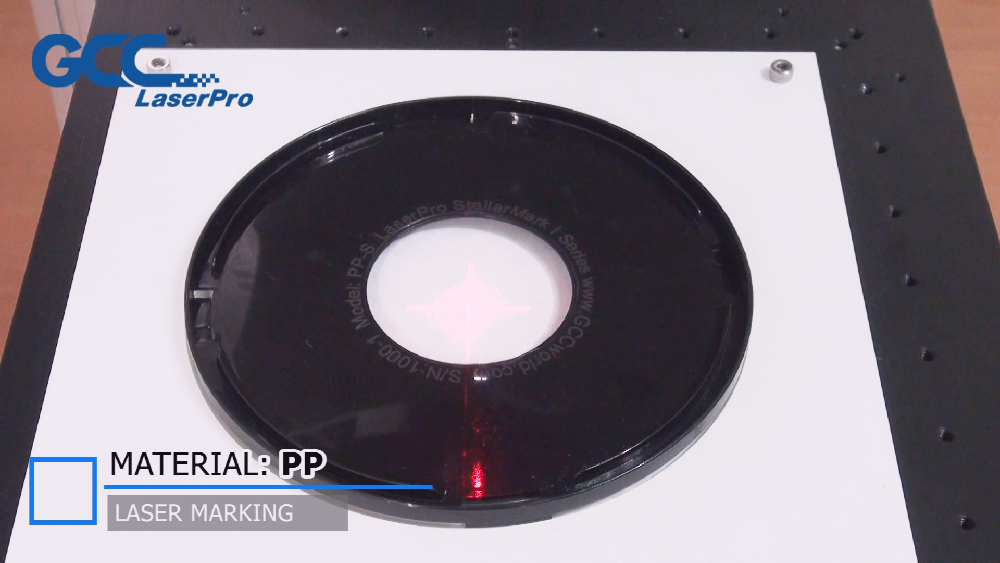

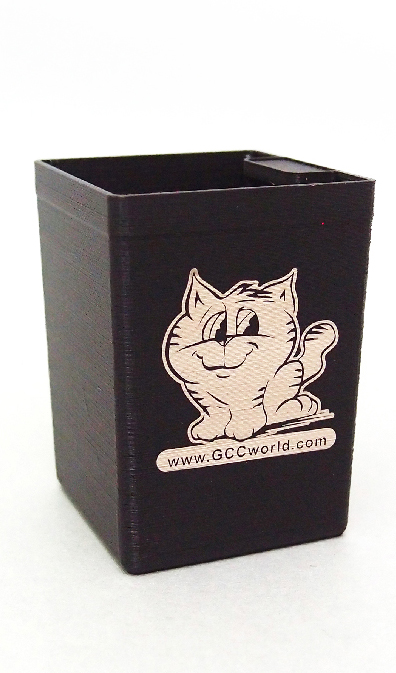

| In laser industry, both CO2 laser and Fiber laser are common and widely used laser sources. As everyone knows, Co2 laser is suitable for processing most of non-metallic materials such as paper, wood, acrylic and cloth, etc.; and fiber laser is particularly suitable for processing of metallic materials. Of course, the applicability of fiber laser does not stop here. With 1064nm wavelength, it is not only capable of processing metallic material but is also able to process some non-transparent plastic materials and shows a completely different effect from Co2 laser. This time, GCC LaserPro application laboratory uses fiber product line (S400, GLS Hybrid, S290, and StellarMark I series) to demonstrate processing of fiber laser on plastic materials for you. If you are worried about how to process your plastic material, take a quick look at the best solution provided by GCC LaserPro application laboratory. Procedures:

| ||||||||||

Sample:

| ||||||||||

| Suggested parameters:

Tips:

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||